In Australia, a significant portion of workplace fatalities is attributed to falls, as well as dropping equipment from heights. In fact, they made up as much as 20% of all workplace fatalities in 2021. The number of survived workplace injuries due to working at heights makes up a similar margin.

It’s not hard to imagine how damaging a workplace injury or fatality can be to a business. Even if the worker is lucky enough to be able to recover from their injuries and return to their duties, eventually, there is a significant amount of manpower, morale, and reputation lost — not to mention the costs that affect a company’s bottom line. Throughout the world, studies have shown that administering standardised safety training can reduce the number of workplace injuries and fatalities per capita. Providing a working at heights course for your construction employees can not only keep your valued members safe but also ensure you don’t have crippling fees that may even put you out of business.

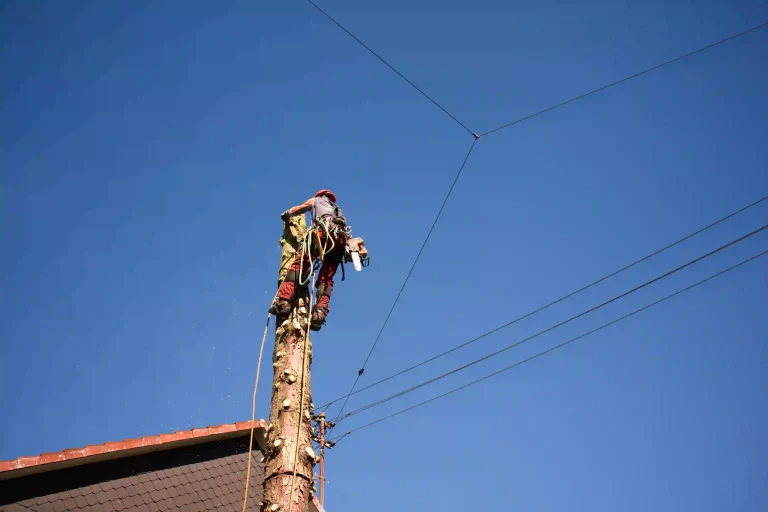

Below are four ways working at heights courses can help keep your business out of hot water, and your workers safe to go home to their families.

1. It Communicates Safety Policy and Requirements to Your Workers

Every single member on a project or job site needs to be well-versed of the training requirements and working at heights risks that are going to be pertinent to a particular job.

Sometimes, one company or job site may have different procedures, policies, and regulations than another. Maybe there’s a danger that’s contextual to a certain location at a facility. Or they had a fatality and decided to double-down on a certain safety precaution in order to ensure the same accident never happens again.

For example, maybe there’s a man lift onsite at a particular location, and they need to do maintenance in a spot that’s up and out of reach from the ground. That means the group of workers are going to need to transition from the basket onto an elevated platform.

Without proper training, they could be exposing themselves to enormous fall risks. They would need to have fitted harnesses and double lanyards so there is always three points of contact when transferring in and out of the man lift basket.

Training should be regularly reinforced so workers are always up-to-date on the latest policies, requirements, and regulations.

2. It Will Help You Get Jobs Awarded to You

Often, the difference between landing a job and getting beaten out by another bidder is the quality of the training your workers have undergone, and the number of certifications they hold.

Sure, every now and then the lowest bid will get awarded the job. But, more often than not, they will be looking for competent, highly trained professionals — especially when there is a high potential for danger.

Making sure all of your employees have undergone a working at heights course will not only show them you’re serious about getting everyone home safely. It also shows professionalism and lends authority to your company name. Clients will rest much easier knowing you’re proactive about safety training — the last thing they want is someone getting injured on their property.

3. Your Workers Will Know How to Set Up a Job Site with Safety in Mind

Working at heights courses begin by ensuring the participant is crystal clear about the basic requirements of job site safety. Anything over 2 metres in Australia is considered a fall risk, thus fall protection must be dawned. Various different types of fall equipment and safeguards may be emplaced to ensure safety is maximised, such as:

- Safety nets

- Scaffolding handrails and toe boards

- Belt restraints

- And various other fall protection mechanisms

4. Your Workers Will Be Trained to Think in Terms of Height Risk Assessment

Your workers need to be taught to perform a very basic level of risk assessment so they can identify all the conditions in elevated areas while operating on a job site. The first and golden rule is — avoid any situation where increased risk is not necessary or there is a significant safety risk.

Nobody’s life is worth climbing out onto a ledge while improperly secured, just to replace a few bolts or operate on a piece of equipment. You’re likely going to run into situations where 100% safety is not possible. But it’s your responsibility to provide them with the means to take the risk as minimal as possible, and it’s their responsibility to identify contextual height risks if they aren’t already identified.

Having trained workers will make sure their mindset is safety-oriented so they know what to identify as a risk and let the appropriate channels know so safeguards can be emplaced.

Working at Heights Training Is an Ongoing Process

Providing a working at heights course for your employees is just the start of a process of the overarching mindset of safety awareness and safety leadership.

You should be communicating the lessons learned during the course before and during every job so the protocols are followed closely on a daily basis.

It’s also worth noting that as helpful as having well-trained workers can be, certain situations require a licensed height safety engineer to determine the proper height safety system is installed in order to conduct operations safely and effectively. This can depend on a variety of factors, such as pitches of roofs, electrical hazards where fall protection is to be installed, etc.

So, make sure you’re doing everything in accordance with the site requirements when setting up a job.

Working with a safety mindset can reduce the number of workplace injuries, keep your business out of a major financial headache, and even ensure everyone goes home to their families — because that’s the most important thing at the end of the day.